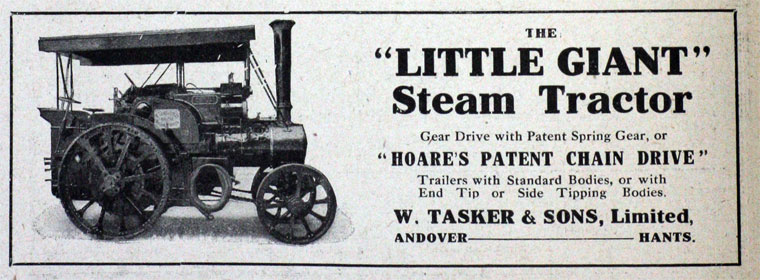

Tasker’s Chain-drive Tractor – The Little Giant

The problem of the springing of the steam tractor has always been one fraught with some little difficulty, for obvious reasons. The adoption of loco-type springs, with self-adjusting spring brackets, on the part of a certain maker marked a distinct advance in the suspension methods of these handy little machines.

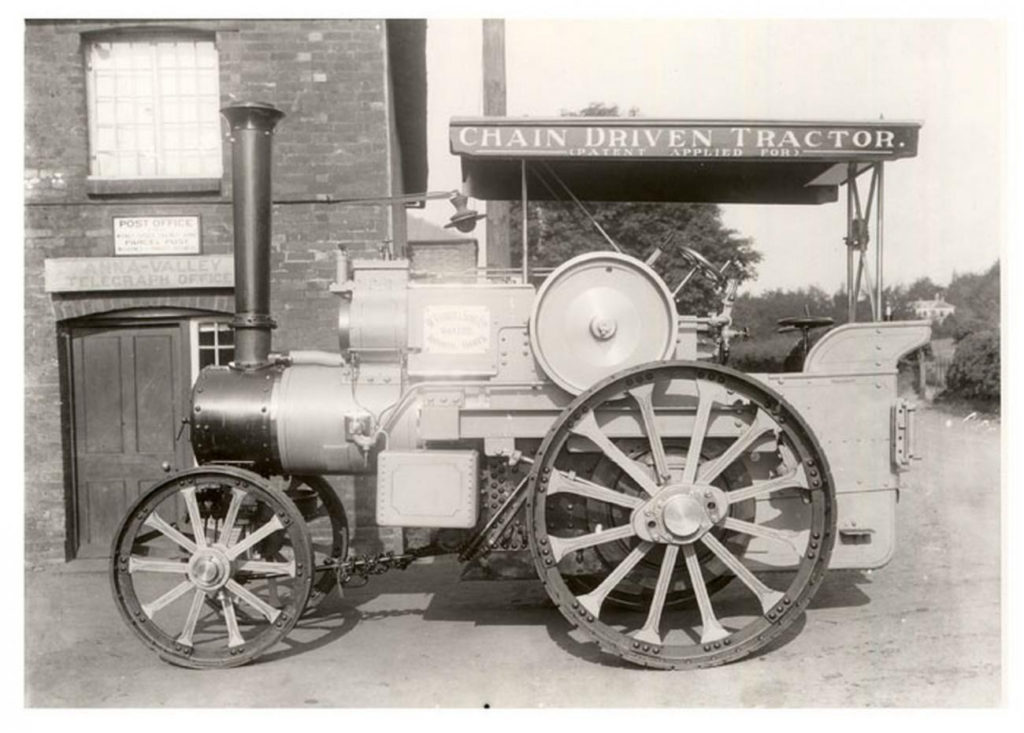

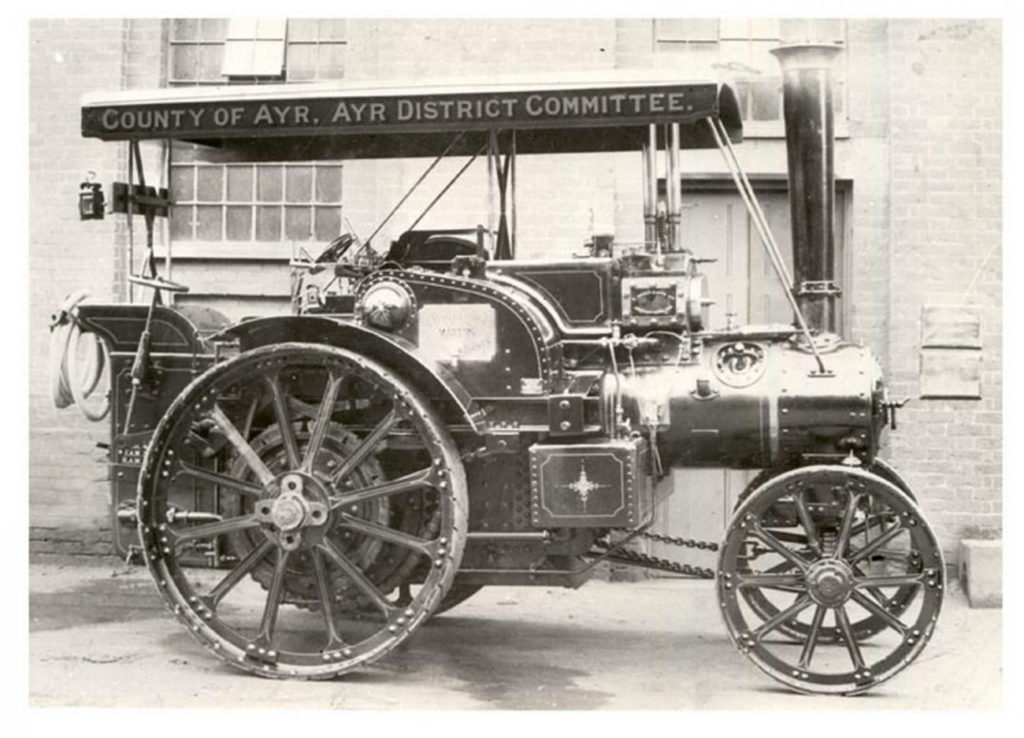

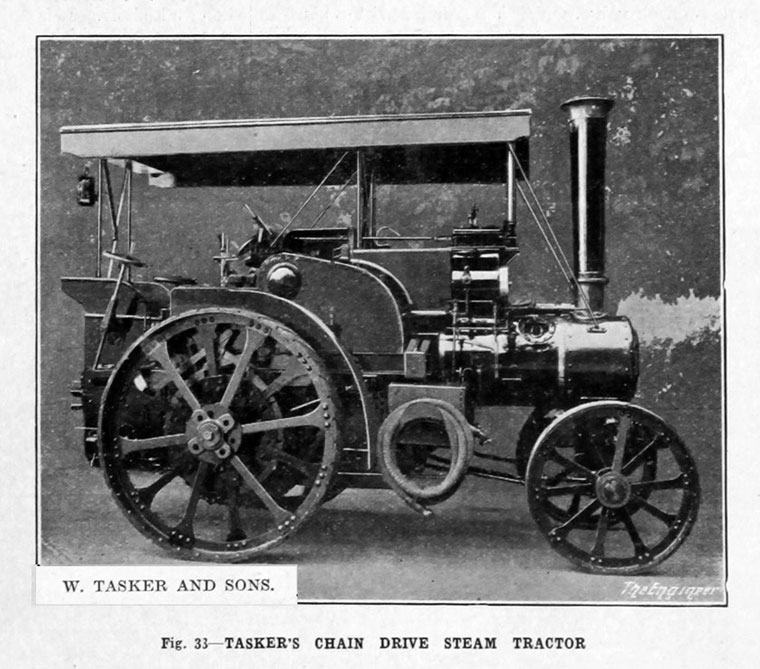

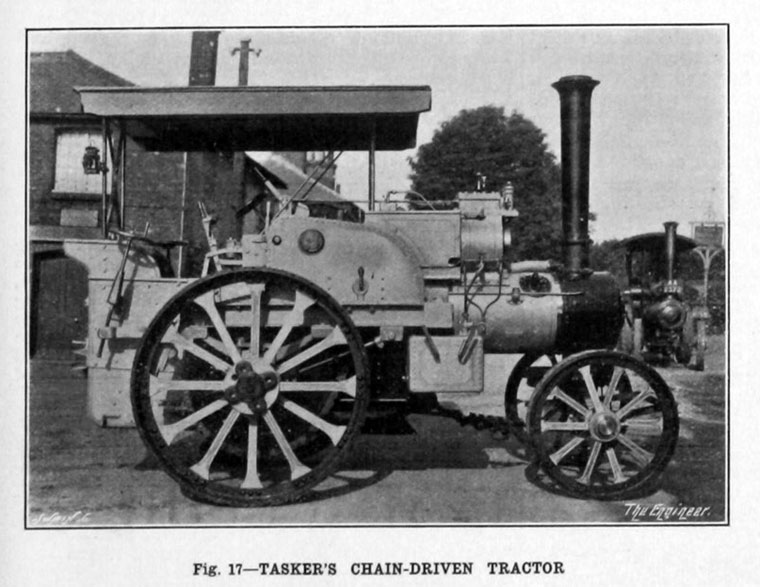

At the Royal Show of 1914, held at Shrewsbury, a new-model, chaindriven steam tractor was staged for the first time by W. Tacker and Sons, Ltd., of Andover. We welcomed this departure in construction as appearing to overcome the mechanical problem which the employment of spur-gear final drive between a sprung engine frame and axle has always presented. Moreover, the springing arrangement itself appeared to be capable, with such a modification, of useful revision.

As it happens, we have not yet had an opportunity of making a practical test of one of these new chain-driven machines, although we have spent a very instructive day doing heavy brewery work in the hilly Kent district on a Tasker five-ton steam wagon.

It is tolerably apparent that this Tacker method, which made its first public appearance in June of last year, was evolved as the result of a careful study of accepted steam-wagon design. The method has been patented by G. Hoare, and the complete specification has now been published. We reproduce below some of the illustrations ac. companying it.

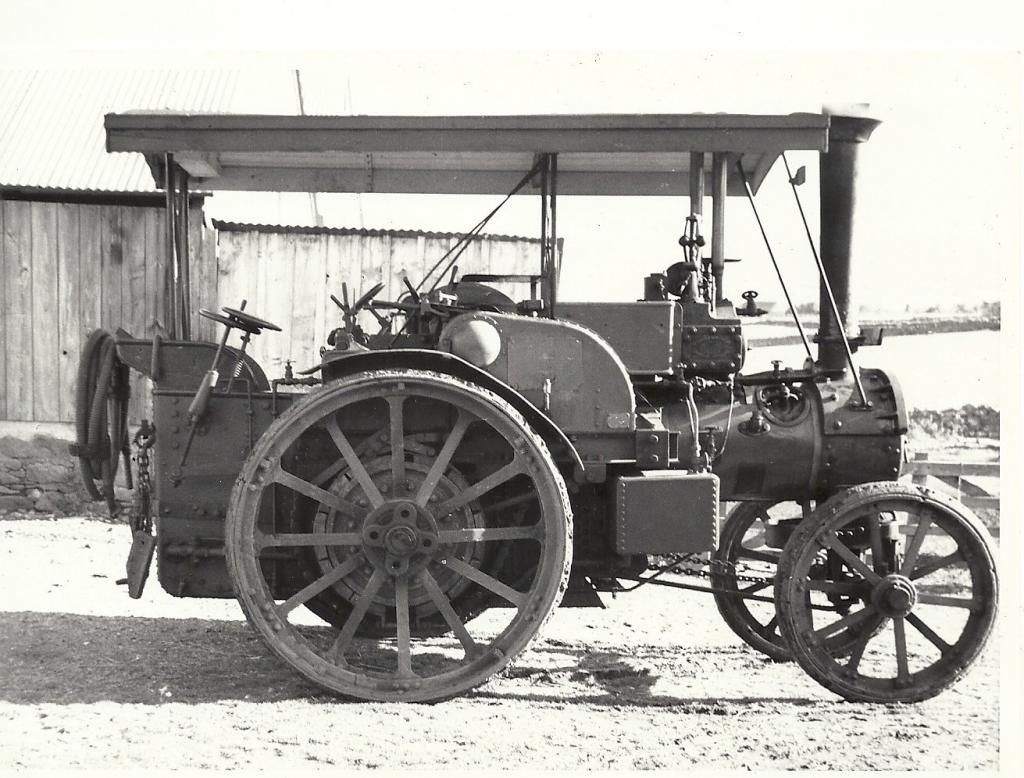

Examination of these drawings reveals the fact that a subsidiary channel-iron frame is now employed, much in the same manner as is found on the majority of Foden-type steam wagons. The ends of these frame pieces are carried in brackets on the boiler barrel and the horn plates, respectively. The ends of the axle driving springs slide under these frame pieces in suitable brackets, and they are arranged, as to the off side, between the chain wheel and the driving wheel, and, as to the near side, between the winding drum and the other road-driving wheel.

The countershaft for the changespeed gear is mounted forward of the crankshaft, in order to provide as considerable a length of driving chain as possible. The driving axle is connected to the main frame by radius rods, -which permit of vertical movement, and this arrangement obviously renders it possible to employ much longer and relatively more flexible springs, in this way securing a much easier-riding tractor. No longer is•the,problem of maintaining proper mesh between the final-drive spur wheel and pinion a pressing one, at any rate on the Tasker.

Source: http://archive.commercialmotor.com/

Originally printed on the 29th april 1915